1.Introduction to Activewear Manufacturing:

In the dynamic world of sportswear, the journey from a conceptual idea to the creation of a tangible activewear piece is a fascinating process that involves creativity, innovation, and precision. Activewear isn’t just about style; it’s about performance, comfort, and pushing the boundaries of design.

The Design Vision:

The journey begins with a vision. Activewear designers seek inspiration from the latest trends, emerging technologies, and the needs of the active individuals who will wear their creations. This initial spark evolves into sketches, designs, and concepts that encapsulate both form and function.

Materials as the Foundation:

One of the pivotal elements in activewear manufacturing is the selection of materials. High-performance fabrics, known for their moisture-wicking, breathability, and durability, play a crucial role. Innovations in fabric technology continually shape the landscape of activewear, ensuring that each piece meets the demanding standards of the modern athlete.

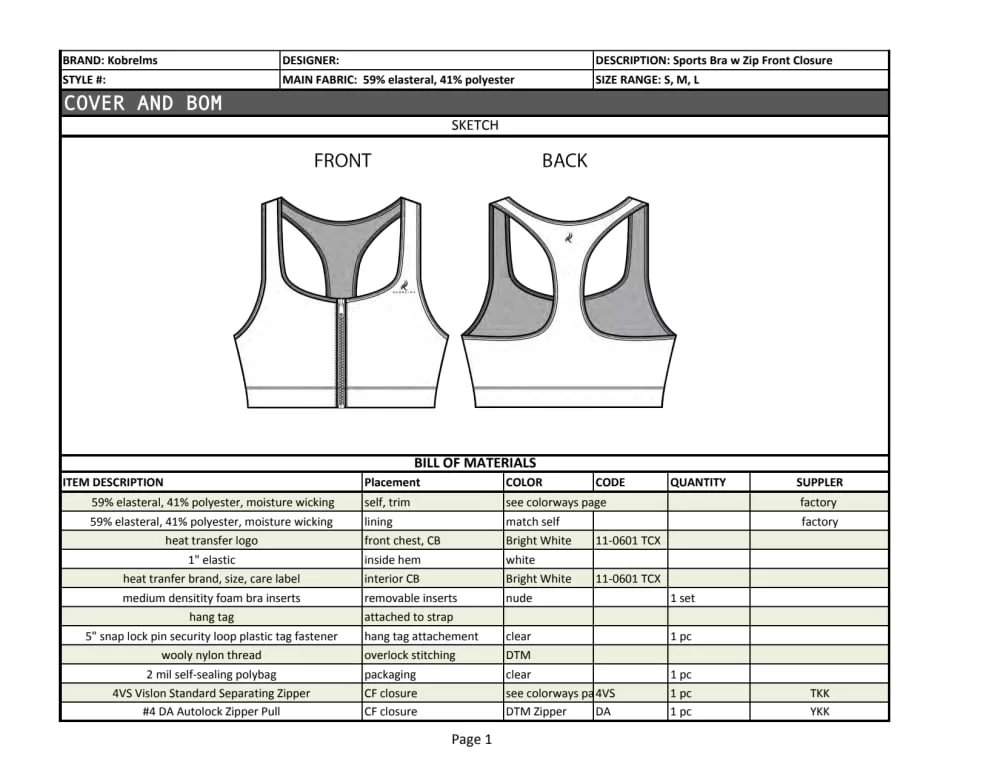

Precision in Pattern Making:

Turning a design into a wearable piece involves the intricate art of pattern making. This phase requires precision and attention to detail, ensuring that the activewear not only looks stylish on the surface but also fits impeccably and supports the body’s movements during various activities.

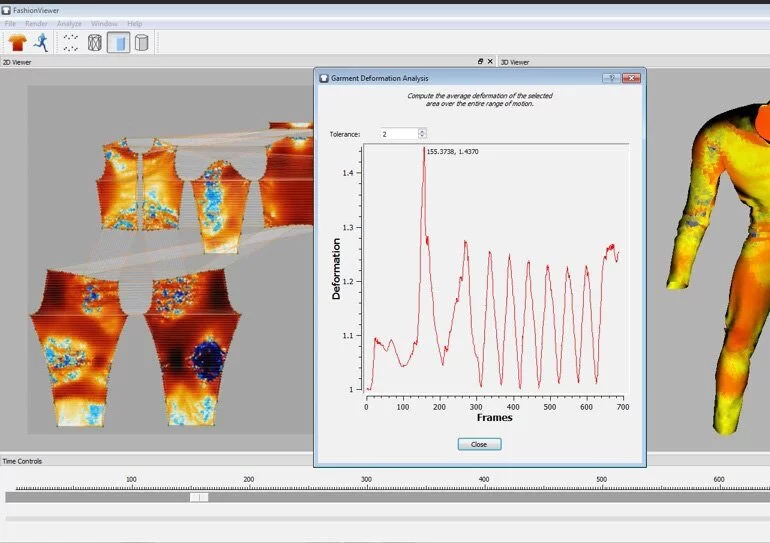

Prototyping for Perfection:

Before mass production begins, prototypes are crafted and tested. This iterative process allows for adjustments, ensuring that the final product aligns with the designer’s vision and meets the performance expectations of the wearer.

As we embark on this journey through the activewear manufacturing process, we’ll delve deeper into the craftsmanship and technology behind each stage. Join us as we unveil the secrets behind the creation of activewear that seamlessly blends fashion with functionality. Welcome to the behind-the-scenes world of activewear manufacturing!

2. Conceptualization and Design Phase:

In the realm of activewear manufacturing, the conceptualization and design phase are the creative heartbeat, where ideas take shape, and style meets function. This crucial stage sets the tone for the entire manufacturing process, influencing not only the aesthetics of the final product but also its performance and appeal to the active community.

Inspiration Unleashed:

The journey begins with inspiration drawn from diverse sources – from the latest fashion trends to insights gained through athlete collaboration. Designers immerse themselves in the world of movement, envisioning apparel that not only looks visually striking but also enhances the wearer’s athletic experience.

Collaboration in Creativity:

The synergy between designers, manufacturers, and clients is pivotal during this phase. Clear communication and collaboration ensure that the envisioned activewear aligns with the brand’s identity and meets the specific needs of the target audience. It’s a dance of ideas and expertise, where each partner contributes to the creation of a unique and market-worthy design.

Functional Fashion:

Activewear is not just about looking good; it’s about optimizing performance. During the conceptualization and design phase, designers carefully balance style with functionality. They integrate features like moisture-wicking capabilities, breathability, and ergonomic designs to ensure that the final product not only looks appealing but also supports the dynamic movements of an active lifestyle.

Sketch to Life:

The design phase sees the transformation of concepts into tangible sketches and renderings. These visual representations act as the blueprint for the manufacturing process, guiding the subsequent stages of material selection, pattern making, and production.

As we delve deeper into the conceptualization and design phase, we’ll uncover the intricate decisions and creative choices that shape activewear into a dynamic fusion of fashion and performance. Join us on this exploration of the artistic origins of activewear, where every stitch and contour is a testament to the commitment to active style and innovation.

3.Cutting and Sewing Techniques :

The cutting and sewing phase in activewear manufacturing is where the artistic vision transforms into tangible reality. This stage is a symphony of precision and skill, where expert craftsmanship and cutting-edge techniques come together to bring the design to life.

Precision Cutting:

The process begins with the careful cutting of high-performance fabrics. Precision is paramount to ensure that each piece retains its intended shape and functionality. State-of-the-art cutting technologies are employed to achieve accuracy, whether it’s for intricate patterns or streamlined silhouettes.

Sewing Mastery:

Once the fabric pieces are cut, skilled seamstresses and tailors take charge. Activewear demands more than just aesthetic appeal; it requires durability and flexibility. Specialized sewing techniques, such as flatlock stitching or reinforced seams, are employed to create garments that withstand the rigors of active movement while maintaining a sleek and polished appearance.

Ergonomic Design Implementation:

During the sewing process, the ergonomic design comes to life. Seams are strategically placed to enhance the overall fit and comfort of the activewear. This meticulous attention to detail ensures that the final product not only meets but exceeds the expectations of athletes and active enthusiasts.

Quality Assurance at Every Stitch:

Quality control is integrated into every step of the cutting and sewing process. Each garment undergoes rigorous inspection to guarantee that it meets the brand’s standards for craftsmanship, ensuring that customers receive activewear that is not only stylish but also built to endure the demands of an active lifestyle.

Innovation in Stitching:

Beyond traditional techniques, the cutting and sewing phase is an arena for innovation. Advancements in sewing technologies and techniques contribute to the evolution of activewear, allowing for greater customization, enhanced performance features, and a seamless blend of style and function.

Join us as we unravel the artistry behind cutting and sewing techniques in activewear manufacturing. From the meticulous precision of the cutting table to the rhythmic hum of sewing machines, this phase is where creativity and craftsmanship converge, shaping activewear that goes beyond expectations.